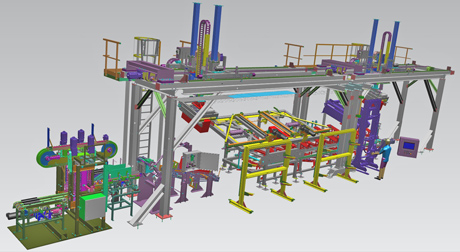

Five roof tiles per second will literally fly through the packing line being assembled by the Single-Purpose Machines Division of MOTOR JIKOV Fostron a.s. for its customer BMI Bramac. And the quarter-tonne packets with up to 42 tiles will leave the line at the end. The high production rate of the packing line poses significant challenges in terms of the quality of the design and the perfect interactions between the software and the machine itself, which is about the size of a small hall. “We are at the design maximum of what we can develop in the Single-Purpose Machines Division. The whole line is then put together at the customer’s site,” said Jiří Prchlík, director of the division.

The packaging line for concrete tiles will be located at Bramac’s plant in Ivanka pri Nitre, Slovakia. Representing half of this year’s turnover, this is the biggest contract for the Single-Purpose Machines Division this year.

While developing the machine, the Division was able to build on a design it had developed for the same customer ten years ago for the latter´s plant located in Chrudim. “It is partly a copy, so we know well we are able to make similar equipment. At a very fast production rate, it is important that both the technical design and the control systems running on the state-of-the-art devices are absolutely flawless. During the design process, we also dealt in detail with materials engineering, where we looked at what materials to use at the points of contact with the tiles, on the sliding surfaces. We chose sintered carbides, which are hard and wear-resistant. They will help us to achieve the reduced costs for spare parts, maintenance as well as less downtimes of the line,” explained Jiří Prchlík.

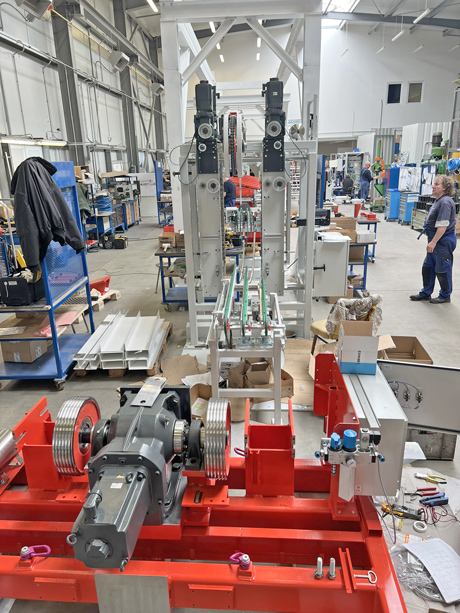

One tenth of the mechanical parts is manufactured by the Single-Purpose Machines Division, while the rest is produced in cooperation. “In terms of size, the structure is beyond our production capabilities. The electrical design and assembly are fully under our control. On the software side, we build on the experience of the previous machine and apply new methods. The design then involved verification of the kinematics and mechanics using the MJG Enix software module. Our people and outsourced engineers who have experience with Siemens control systems are working on the software,” said Jiří Prchlík.

The programmers are debugging the line programme, while the mechanical and electrical parts are yet to be finished. “By the late July we should complete the tests at the supplier´s place, and the actual installation and commissioning in Slovakia is planned for the end of the year. As in recent years, we are struggling with long delivery times, for example in the production of switchboards. We are literally looking for material wherever we can. However, the production is running in line with the proposed schedule,” added Jiří Prchlík.

The Single-Purpose Machines Division of MOTOR JIKOV Fostron a.s. plans to further develop its cooperation with BMI Bramac. “The customer is satisfied with our work and has ordered additional sub-machines for its plants in Germany and Romania. We also offered two lines for cleaning tile moulds; we currently have nine of these across Europe. But we can only handle smaller contracts this year,” the director explained.