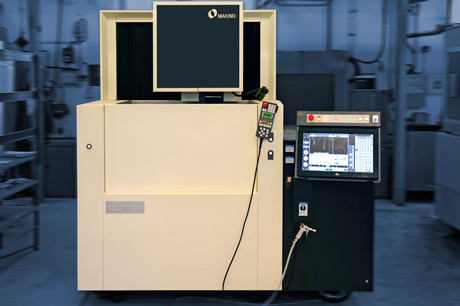

Contributing to increased production capacity, a new wire EDM machine worth four million CZK has been acquired with partial funding under the project to expand the MOTOR JIKOV Foundry's Technological Development Center.

"Due to rising production demands, the capacity of the existing MAKINO EU64 machine was no longer sufficient. The selection process and tests were conducted between Penta, offering the Fanuc Robocut C 600i, CUT 300Sp machine, which was proposed by +GF+, and MAKINO with the U6 H.E.A.T. machine. After evaluating the tests and comparing the price-performance ratio, we chose the MAKINO machine," said Jiří Boček, Production Manager of the Molds Division.

The machine was delivered in April, and its operators were trained at that time. Currently, trial operation is underway and production is gradually ramping up. "We use the wire EDM machine for cutting precise holes in mold inserts, mold cores, punches, and matrices for cutting tools. On the new machine, we will mainly cut holes in mold inserts, while the old wire EDM machine is used for mold matrices, punches, and smaller parts," added Jiří Boček.

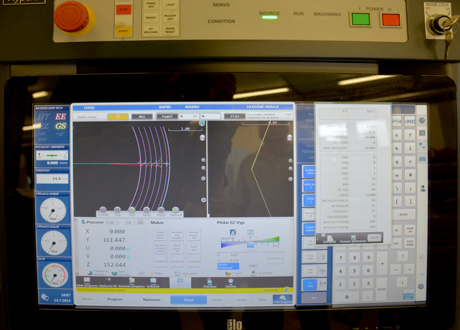

"This is a very high-quality machine with the most modern control interface in the form of a large twenty-four-inch touch display," praised Tatyana Uzunova from Makino.

The main difference compared to the old machine is the ability to cut taller parts. The current machine has a Z-axis stroke of 260 mm, while the new one offers 420 mm.

+125

years in the market

Kickstart your career at Motor Jikov – take a look at our job openings and get in touch with us.

MOTOR JIKOV Group a.s. company utilizes the opportunity to draw funds from European program grant resources.