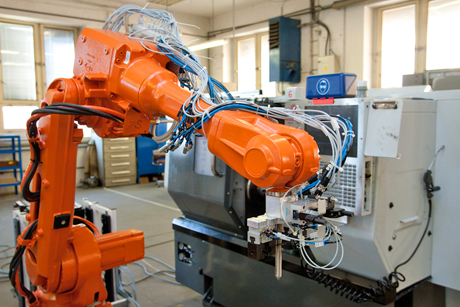

The Single-Purpose Machines division has developed and manufactured a robotic workstation for operating CNC lathes. This equipment, where robots work in conjunction with machining tools, is designed for machining and handling spherical pins for passenger vehicles.

The workstation, measuring 6.5 x 6 meters, consists of two six-axis robots, each operating one CNC lathe. "The robots' job involves gripping the blank from the vibratory feeder, positioning it into the CNC lathe's chuck, and after machining, the robot removes it again, measures it with a camera, and places it into a pallet stand with finished parts," describes the workstation's designer Marie Kovaříková. The robots operate independently, although some operations are shared, such as raw material dosing or pin measurement.

"This is our first project involving the cooperation of robots and machining tools. The most challenging part was integrating control systems and achieving 100% synchronization of the robots with individual stations, such as feeders, conveyors, and unloading areas," adds electrical engineer Jiří Prchlík. "The customer had specific requirements for maximum performance and high flexibility to adapt the workstation for other projects, with quick reconfiguration within approximately 15 minutes. Overall, this is a very interesting project, and we would like to offer the experience gained to other clients as well."

+125

years in the market

Kickstart your career at Motor Jikov – take a look at our job openings and get in touch with us.

MOTOR JIKOV Group a.s. company utilizes the opportunity to draw funds from European program grant resources.